Project OblitR8!

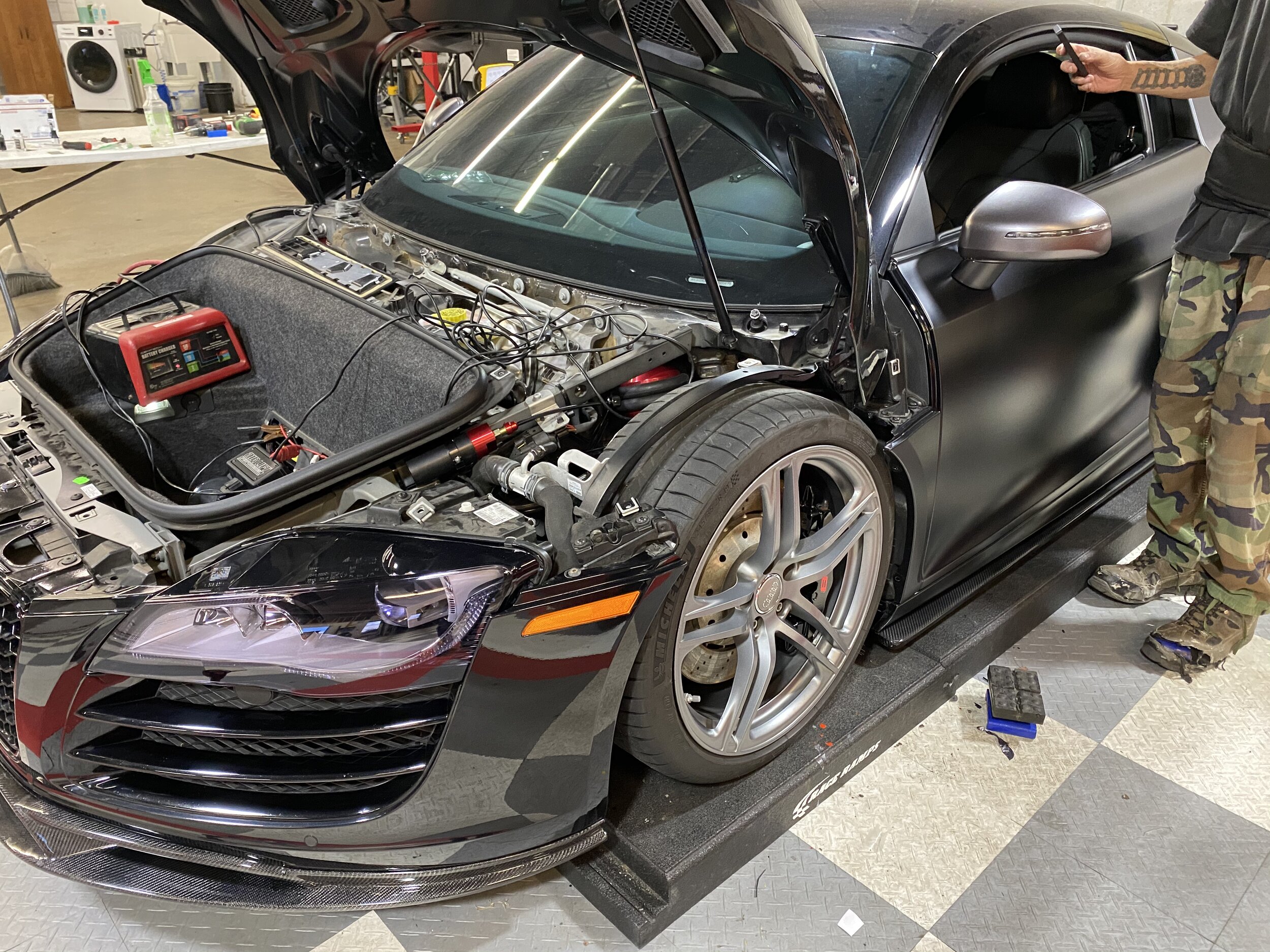

2012 Audi R8 (1st Gen)

5.2L V10 Engine

Gated 6 speed manual transmission

Phantom Black Pearl Paint

29k Miles

Services

Custom Rendered Design

PPF Removal

Matte PPF Aesthetic Install

Clear PPF Installed on all Carbon Fiber Aero

Custom PPF and Vinyl Install

Ceramic Tint Installed on fronts and windshield

Tinted Headlights, Taillights and Sidemarkers

Custom Aero Installed

Custom Trunk Display

Wheels and Exterior Coated with Ceramic Pro

Parts

Vossen Forged EVO-3R 3-piece wheels

Michelin Pilot Tires

Airlift Performance 3H Management

Airlift Performance Custom Built fully adjustable Air Shocks with remote reserviors

Euro Boutique Front Carbon Fiber Spliter

Euro Boutique Carbon Fiber Rear Lip Spoiler

German Rush Carbon Fiber Side Splitters

German Rush Carbon Fiber Diffuser

Completed

October 2020

PPF Removal and General Prep: Dom

Corrections and Coatings: Snarky

Custom Aero Install: Matt

PPF and Custom Vinyl: Matt and Ross

Airride Custom Install: Nick

Custom Design: Ross

Backstory

Our client was looking for an Audi R8 V10 ideally in black with a red interior and it had to have a manual transmission. Normally you would just go to your local dealer and order the exact car you want, however, Audi stopped making this car in a manual transmission in 2015. So the search began and we called our friend Doug over at Switchcars in Twinsburg. Doug had an excellent example with less than 30k miles in Phantom Black Pearl with matching side blades and black interior. Everything checked out mechanically and the paint was fully wrapped in PPF, so basically as close to perfect as we can get with a manual transmission!

Design Process

The goal with this project was to take the older generation R8 and turn it into a real stunner that can compete with the looks of the newer models. The entire design process took about a month of going through various product options and styles with the client to really dial in the right look. The biggest design challenge for this build was to give it some pop and still keep a very dark, sinister theme. With that in mind, we created a rendering to show everything we were planning to do. The rendering alone took nearly 14 hours, but the end result was totally worth it. The client’s response to seeing the rendered design was an overwhelming yes with how soon can we start!

Parts

Any project will have lots of parts to order, but at this level, several of the products had to be custom made. The Vossen Forged wheels took nearly 3 months to come in from Miami; the airride components were assembled to order at Airlift in Arizona and several of the Carbon Fiber aero pieces had to be handmade as well. A project this involved takes some patience but thankfully the R8 has a lot of options to choose from!

Services

To get this project moving, we had to remove the existing PPF. Some panels left significant adhesive and took hours to remove. There were a few rock chips that needed some light touch up and the paint was polished to a mirror finish. To get the specific look our client wanted, we used STEK DYNOMatte matte PPF. It uses the original color but adds a deep matte sheen and protects the factory paint for years to come. The roof received a brand new product from STEK called DYNOBlack Carbon which is the most realistic Carbon Fiber Simulation wrap ever. The side blades and mirrors were wrapped in 3M Satin Grey Metallic to offset the matte finish while still keeping the overall theme.

The existing tint was stripped and STEK Smart series Ceramic Tint was applied to the glass. Ceramic Tint offers the best in clarity and blocks over 85% of the Infrared (IR) heat from the sun. We used 35% on the side windows and 70% on the windshield. The engine glass was left clear for a better view of the V10 powerplant. We also used STEK DYNOSmoke on the taillights and side marker lights and DYNOShade on the headlights. These are PPF grade films with exceptional clarity and longevity.

One aspect of the R8 that was hard to upgrade was the wheels. The factory wheels are forged, lightweight wheels in a timeless split 5-spoke design. In order to really upgrade the look of the car, the wheels had to change. We went straight to Vossen and put together a killer set of their 3-piece forged wheels. After looking at many amazing designs, we settled on the newly released EVO-3Rs. We ordered an upsized 20” rear wheel and pushed the front and rear wheels outward about 1/2” to give it a wider stance and more presence. The wheels themselves were able to be custom finished and we designed them with gloss black lips, dark smoked faces and Vossen’s signature red barrels. The exposed hardware and the Vossen forged lugs were gloss black. We utilized some advanced techniques in applying 2 layers of Ceramic Pro to the intricate wheels with an airbrush. This will provide years of protection and ease of cleaning. lastly the wheels were wrapped in OEM Spec’d Michelin Pilot Tires and high-speed road force balanced. They are now ready for 200mph!

Now with the wheels looking insane, altitude was the next issue to fix. Airlift Performance Airride suspension was chosen for several reasons. Most importantly it had to perform at least as good as the factory magnetic ride suspension which is a tough act to follow. It also allows for different driving heights like crusing mode, track mode, completely airred out and up mode to clear large obstacles. Airlift Performance really came through with shinning colors, all of their components work seamlessly together to give the ultimate in ride, looks, performance and even reliability. We went a little overboard (as we often do) and built a custom display for the airride components in the front trunk while still maintaining an OEM style appearance.

The most important part of bringing this car into a more modern design look was the aero components. The components were carefully chosen to give it a wider, lower and more aggressive look while still being an overall OEM inspired theme. We used hand-laid Carbon Fiber components from Euro Boutique and German Rush to provide the high quality look and feel that was a must for this project. The lower edge was finished off with a subtle red vinyl stripe to accentuate the new stance. STEK DYNOSheild was used on all of the Carbon Fiber components to provide massive gloss and protection for years to come.

For the ultimate longevity and ease of maintenance we protected everything with Ceramic Pro. The 2 layer system is comprised of the Vinyl & PPF Base Coat and Top coat which makes the surface super slick and chemically resistant. This ensures that the Various PPF surfaces as well as the wheels and glass will always be protected and easy to keep clean for years to come!

Final Result

Rehab Automotive Restyling has always been known for their exotic and high-design custom builds, however, Project OblitR8 was one of our biggest projects to date! Scroll through our project gallery for before and after photos as well as some of our exclusive photos of the work being completed!

Enjoy the photos and reach out here to get your custom project started!